IVF Turnkey Project Management

The term “Turnkey” describes a project in which the service provider takes the single point responsibility to complete the project in all aspects and hands it over to the owner in a ready to use state. Any project execution must take care of schedule (timeline), cost and quality.

Shivani Scientific with its Turnkey management expertise will help in evaluating a workable plan where all the necessary processes, equipment, and construction will be integrated into a cost-effective and performing solution.

To realize the fruition of an IVF clinic in every detail encompassing instrumentation, floor plan, AHU unit and even maintenance of a positive pressure will be succeeded with the support of our team of experts who have been successful to materialize your fully compliant and functional ART unit for years.

TURNKEY PROJECT ELEMENT

Master Plan:

Welcome to our world-class integrated gamete and embryo treatment facility (IVF) solution - the Turnkey Projects Global Solutions! If you're considering starting an ART center, we understand that it can be an overwhelming process. Our turnkey solution integrates all the necessary processes and equipment, providing a cost-effective and high-performing solution. With over 1400+ ART centers commissioned and supported in 35+ countries, Shivani has a proven track record of success.

We take pride in our ability to deliver tailored solutions to meet your unique requirements, ensuring that your ART center is fully compliant and equipped to provide world-class treatment to your patients. Partner with us to take your first step towards success in the ART industry

Action Plan

The IVF lab facility:

The facility for IVF laboratory is an essential workspace within the ART center. It is where eggs, sperm, and embryos are handled and processed under specific disinfection and sterilization protocols. The primary focus in designing this space is to meet the standards for internal air quality (IAQ). Depending on the standards implemented, the facility can be categorized into Grade A, Grade B, Grade C, or Grade D.

Sample Procurement:

In the field of assisted reproduction, the procurement of biological samples such as spermatozoa and oocytes is a crucial aspect. Unlike other tissue banking areas where specimens are obtained from various sources, gamete donors are involved in assisted reproduction. It is important to note that these samples cannot be disinfected or sterilized before use in the IVF laboratory, as they must undergo open procedures during the in vitro fertilization and embryo culture process. As such, it is imperative to ensure that the procurement of these samples is carried out with the utmost care and diligence to maintain the integrity of the samples and the safety of all parties involved.

Sample Handling & Processing:

When designing an IVF lab, the primary goal should be to ensure the quality and safety of transplanted tissue and cells. This necessitates the adoption of handling protocols that minimize the risk of infection and transmission of diseases. Additionally, it is essential to ensure that the processing procedures do not compromise the functional potential of the cells. In other words, the laboratory should be designed in a way that ensures that the handling and processing of specimens are carried out with utmost care and precision to preserve their integrity while maintaining safety standards.

Positive Pressure Design:

In order to minimize the risk of contamination from surrounding areas, the IVF lab should be designed with positive pressure. This involves providing fresh air intake to replace the CO₂ gas released within the lab. By doing so, not only are the embryos protected, but the embryologist as well. The positive pressure design ensures that any contaminants or pollutants from outside are effectively kept at bay, which is crucial for the success of the IVF process. Furthermore, this design ensures the safety of the embryologist by creating a controlled environment that is free from any harmful particles or pathogens that could compromise their health.

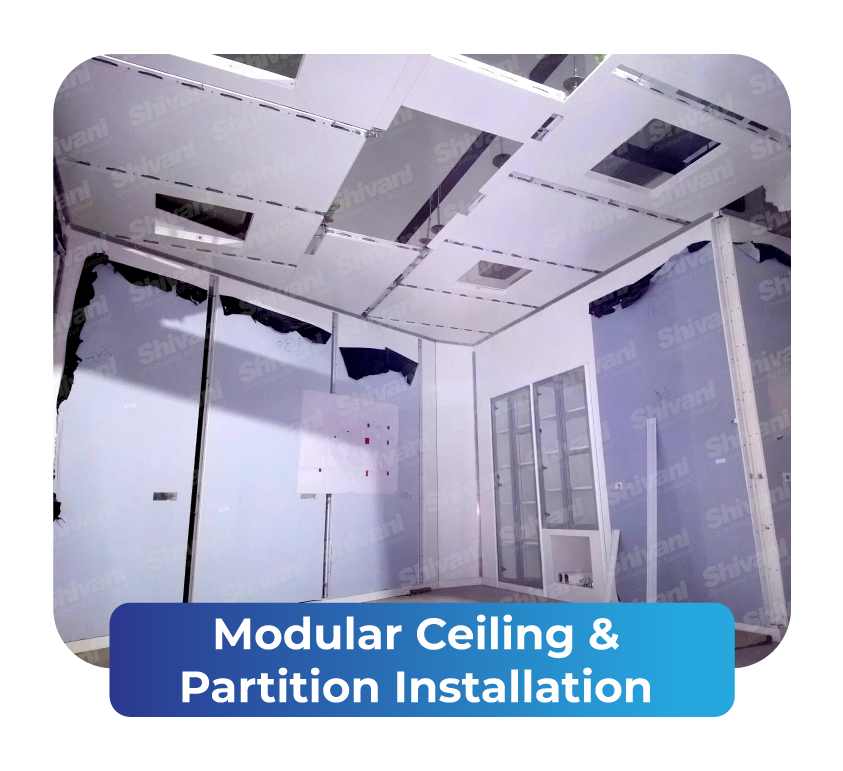

Modular Clean room & air quality:

In the context of modular clean rooms and air quality, it is essential to establish the required air grades, which range from A to D. To minimize the level of microbial contaminants, HEPA and VOC filtration systems can be utilized, along with a modular clean room design. The modular clean room concept offers several benefits, including ease of partitioning, effortless clean ability, and the ability to curve joints while providing provisions for electrical and gas pipelines. Moreover, the design achieves an optimal aesthetic appearance that is both appealing and functional. By adopting such measures, the air quality is improved, and the risk of contamination is significantly reduced, ensuring that the modular clean room remains a safe and efficient workspace.

Traceability:

In addition to the design considerations for the IVF lab, it is also important to establish appropriate standards for traceability of specimens. This entails setting labeling specifications and determining the requirements for data retention. By doing so, it becomes easier to track the origins of each specimen, maintain accurate records, and ensure that all specimens are handled and processed in a manner that meets the established standards. Ultimately, traceability is critical in ensuring the quality and safety of the specimens used in the IVF process, and it is imperative to incorporate these requirements into the design of the lab.

Modular Operation Theaters

A modular operating room (OR), also known as a modular surgical suite or modular theater, is a specialized medical facility designed for surgical procedures. What sets a modular OR apart from a traditional operating room is its modular and flexible design

As a provider of modular operating rooms, Shivani aims to deliver cutting-edge solutions that enhance the surgical environment. Our modular ORs prioritize safety, precision, and efficiency, ensuring a streamlined workflow and improved patient outcomes.

Advantages of SHIVANI Modular Operating Theaters:

Modular wall systems are designed for clean rooms and come with a silver ion coating to protect against microorganisms.

These systems are designed for easy upgrades and clean implementation.

Materials for the wall systems can be individually selected and include options like galvanized painted steel plate, silver ion-coated steel plate, stainless steel, and silver ion-coated stainless steel High-Pressure Laminate (HPL)

Features of SHIVANI Modular Operating Theaters:

Surfaces made of galvanized sheet steel, aluminum, or stainless steel.

Finished with certified, antimicrobial powder coating.

Excellent resistance to chemicals and mechanical wear and tear.

Wall thickness: 50 - 80 mm.

Radiation protection furnishings available for solid walls, glass elements, and doors.

Utility supply units for medicinal gasses and electrical supplies.

Flush vertical air ducts integrated into the walls.

Manual and automatic single-action and sliding doors.

Flush wall-integrated furnishings.

Ceiling system with ergonomically optimized surrounding lighting.

Benefits of SHIVANI Modular System Solutions:

Suitable for complex installations in various clinical applications.

Offers flexibility and individuality.

Easy dismantling and re-installation by non-specialized workmen.

Simplifies technical retrofitting and cost-efficient repairs.

Planking material options include highly resistible HPL in different patient-oriented designs, galvanized, powder-coated, and stainless steel.

Additional Features:

Doors and windows wall-flush integrable upon request.

High stability and resistance of wall elements against damage and humidity.

Hermetically sealed door option available if needed.

Ceiling-high wall elements and grid widths up to 1250 mm to reduce joint parts by up to 80%.

Dry construction without humidity content.

Antibacterial, fungicidal, and microbiologically harmless wall finish.

Electrical and water installations ready for connection, integrated.

Apertures for wall internals industrially manufactured ex-works.

Own-produced windows and doors for flush-mounted assembly.

High degree of prefabrication ensures short construction times and reduced investment costs.